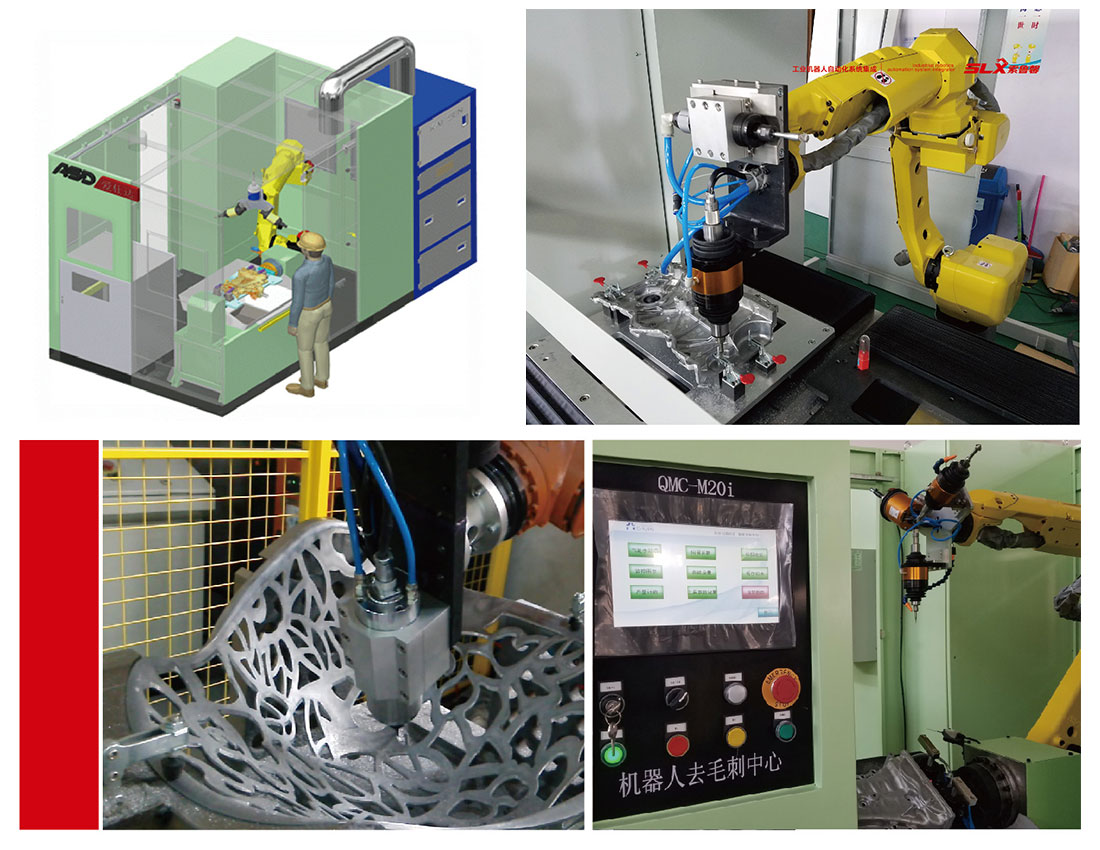

Robot takes the workpiece to the deburring workstation

Deburring Workstation (Casting Aluminum) Standardization, Modularization and Prefabrication Second Generation Deburring Workstation

■ Integrated Sheet Metal Workshop

■ Rotary feeding/sliding table feeding

■ Robot takes tools/workpieces

■ Multi-robots Co-operation

■ Flexible Working Group

■ Die Cast Aluminum, Cast Aluminum, after machine processing

Robot takes the workpiece to the deburring workstation

Deburring Workstation (Casting Aluminum) Standardization, Modularization and Prefabrication Second Generation Deburring Workstation

■ Integrated Sheet Metal Workshop

■ Rotary feeding/sliding table feeding

■ Robot takes tools/workpieces

■ Multi-robots Co-operation

■ Flexible Working Group

■ Die Cast Aluminum, Cast Aluminum, after machine processing

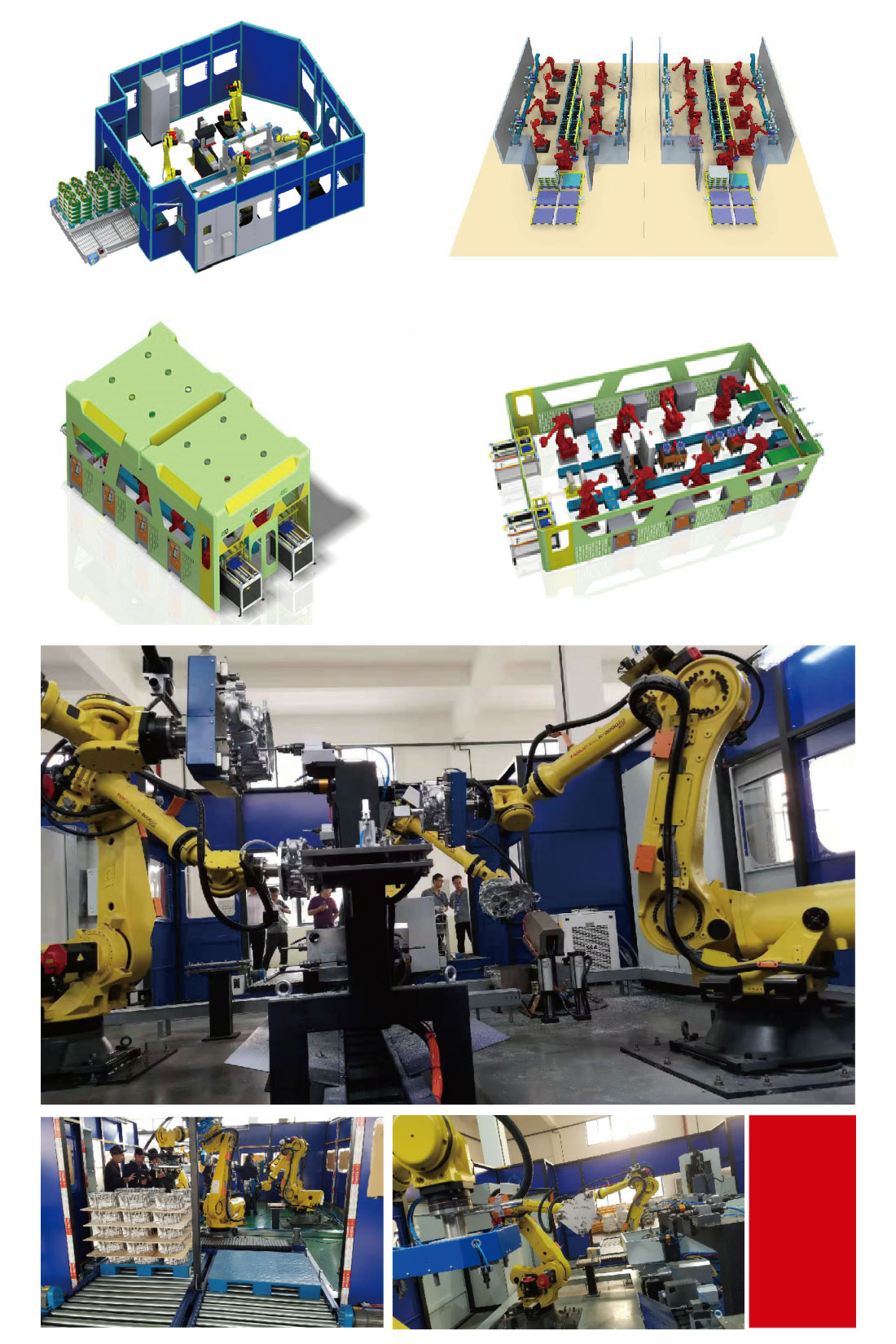

Robot take the workpiece to deburring workstation

Features: Strong practicability

Standard components

■ 6-Axis Robot

■ Displacement mechanism

■ PLC Logic Control Unit

■ Fixture (set)

■ Integral Protective and Central Dust Collector

■ Radial flexible spindle

■ Axial flexible spindle

Multi-Robot Cooperative Deburring

Features: Automatic stacking function, high grinding accuracy, fast rhythm (Expansibility in the later stage, can achieve unmanned production)

Standard components

■ 6-Axis Robot

■ PLC Logic Control Unit

■ 3D vision

■ IPC

■ Quick change mechanism (1 set)

■ Grasper (4 sets)

■ Radial flexible spindle

■ Scrap Removal Machine and Boring Machine

■ Fixed Workbench

■ Integral Protective and Central Dust Collector

■ Axial flexible spindle

■ Reserve multiple digital system interfaces

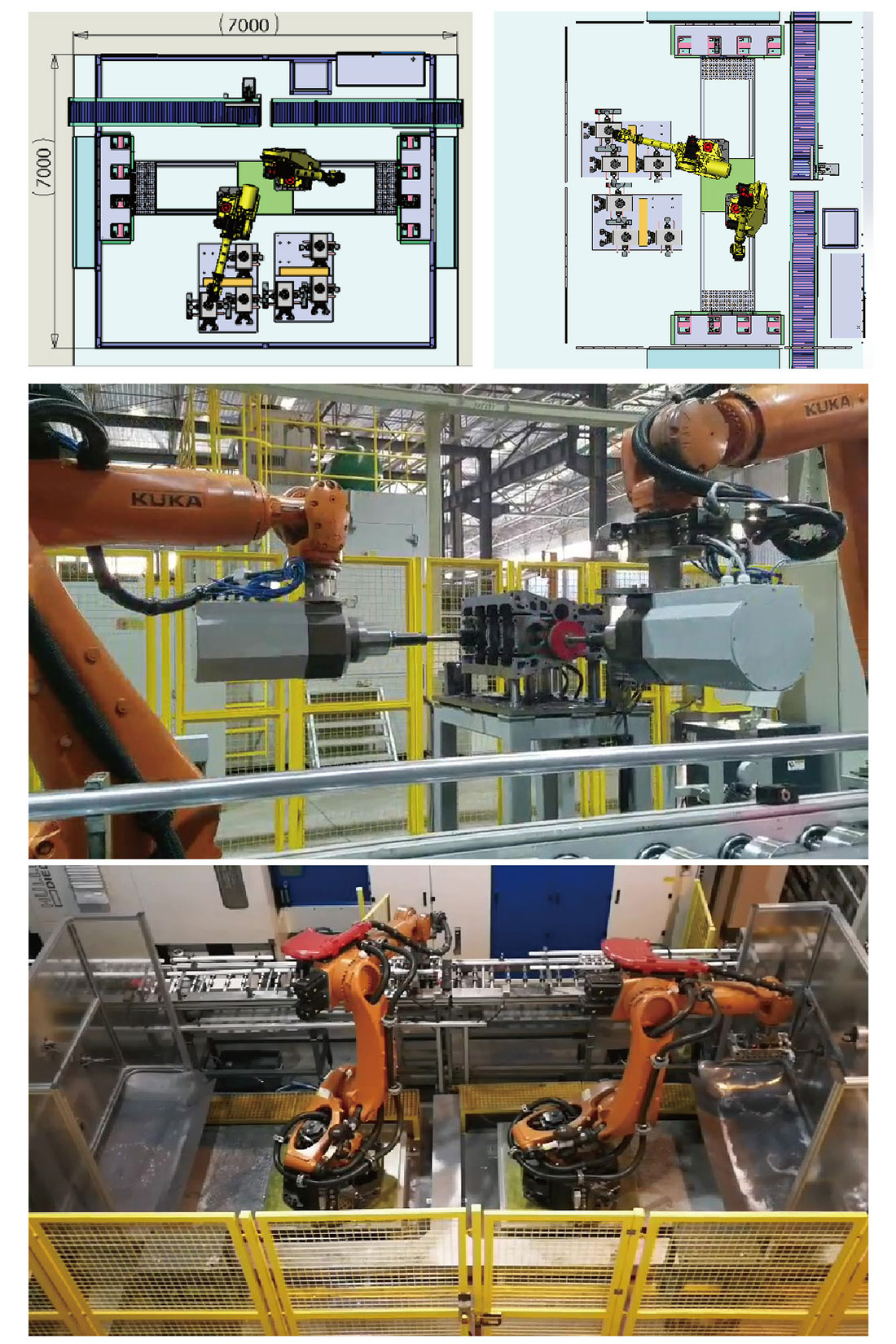

Deburring Workstation after Machine processing

Features: It realizes the function of automatic grasper switching, and realizes the automatic switching of many kinds of products (Expansibility in the later stage, can achieve unmanned production).

Personnel change tools outside the processing area to avoid potential accidents

Small area, easy to expand

Using dual robots

Each machine completes the grinding process independently and has good redundancy.

The polishing rhythm is more abundant, avoiding the phenomenon that burrs become bigger and dirty due to the wear of machined tools.

沪ICP备19013207号

沪ICP备19013207号